CNC Machines

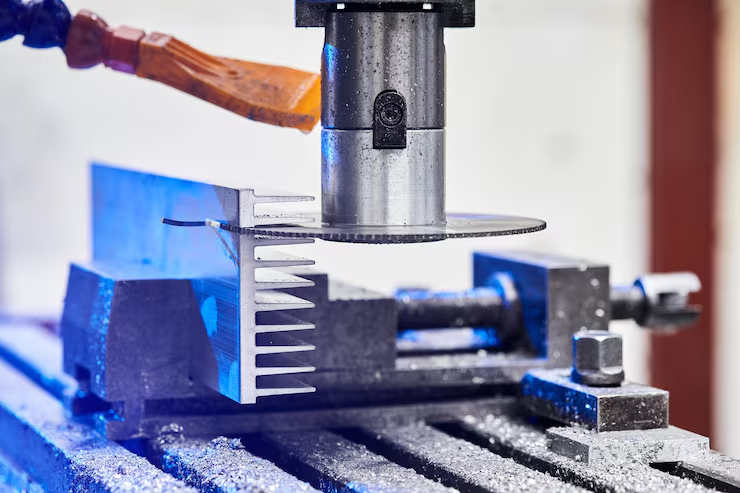

Lean-60 CNC Machine |

Features

- Rigid cast-iron structure for vibration-free operation

- Linear guideways for smooth and fast axis movement

- Centralized lubrication system for extended component life

- Enclosed CNC enclosure with coolant management

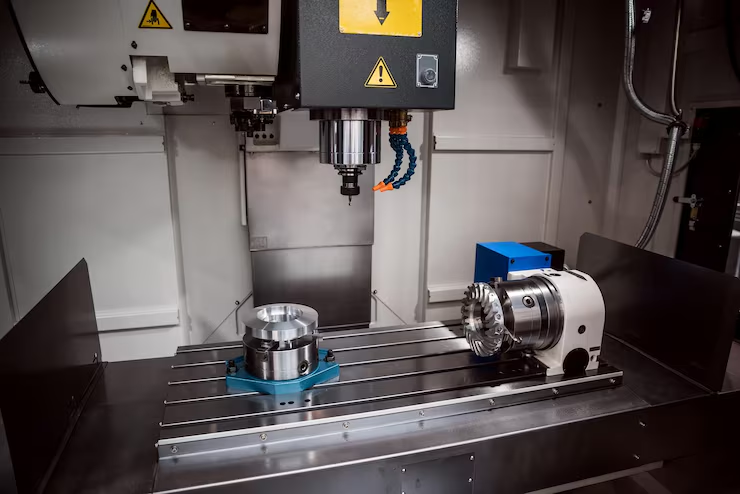

Lean-100 CNC Machine |

The Lean-100 CNC Machine is a powerful and versatile vertical machining center designed for medium to heavy-duty machining applications. It combines precision engineering with robust construction, offering exceptional performance, accuracy, and reliability.

Engineered for industries that demand high productivity and superior surface finish, the Lean-100 delivers consistent output across complex machining operations — from automotive parts to precision dies and molds.

Features- Heavy component machining

- Automotive and aerospace manufacturing

- Precision die and mold fabrication

- Industrial machinery parts

ATR-150 CNC Machine |

The ATR-150 CNC Machine is a high-precision, heavy-duty machining center designed for advanced industrial applications. Built with a robust structure, powerful spindle, and intelligent control system, the ATR-150 delivers exceptional accuracy, rigidity, and productivity — even under demanding machining conditions.

Developed for large component manufacturing, it offers enhanced machining flexibility, making it ideal for industries like automotive, aerospace, mold-making, and general engineering.

Features- Robust cast structure for stability during long machining cycles

- High-speed servo motors with precision ball screws

- Automatic centralized lubrication system

- Enclosed body for noise and coolant containment

ATR-250 CNC Machine |

The ATR-250 CNC Machine is a high-capacity, heavy-duty vertical machining center engineered for precision, power, and productivity. Designed to handle large and complex components, the ATR-250 delivers unmatched machining accuracy, rigidity, and performance even under extreme cutting conditions.

With a robust structural design, advanced CNC controls, and intelligent automation options, it’s the perfect solution for industries that demand high-output machining with superior accuracy — including automotive, aerospace, energy, die-mold, and heavy engineering.

Features- Extra-large table and travel for heavy workpieces

- Rigid column and base casting for excellent structural stability

- High-speed servo drive system for faster cycle times

- Centralized automatic lubrication and coolant system

Vijayta Double Head |

The Vijayta Double Head CNC Machine is a high-efficiency dual-spindle machining solution designed for simultaneous operations on two components — doubling productivity without compromising precision. Built for speed, accuracy, and reliability, it’s the perfect choice for mass production and batch machining in industries like automotive, aerospace, electrical, and general engineering.

Engineered with a robust structure, synchronized control system, and intelligent automation, the Vijayta Double Head CNC offers unmatched performance in drilling, tapping, milling, and contouring operations.

Features- Dual independent CNC spindles for parallel machining

- Linear guideways for smooth and fast motion

- Centralized lubrication and coolant circulation

- Fully enclosed structure with chip and splash protection

Get In Touch

- Street No. 3, Gill Rd, opposite N S P School, Shahid Jasdev Singh Nagar, Ludhiana

-

+91-7814065565

+91- 6284401026

+91-0161-5042084 - info@autotuners.com

QUICK LINKS

- - Home

- - Company Profile

- - Our Products

- - Facilities

- - Contact Us